- HOME

- ABOUT US

- Equipment

- Food Processing Plants and Line

- Tomato Ketchup Processing Plant

- Fruit Juice Processing Plant

- Fruit Pulp Processing Plant

- Dairy Processing Plant

- Vegetable Processing Plant

- Food Processing Line Equipment

- Meat Processing Machine

- Nuts Processing Machine

- Food Packing Machine

- Snacks Making Machine

- Milk Processing Equipment

- Tea Bag Machine

- Food Forming Line Machines

- Relief Blankets and Tents

- Agricultural Machinery and Equipment

- Tractors

- Tillage Implements

- Sowing Equipment

- Harvesting Equipment and Combine Harvesters

- Threshers, Reaper and Binders

- Crop/Grain/seeds Cleaning, Grading and Weighing Equipment

- Weeding and Intercultural Equipment

- Plant Protection Equipment

- Maize Shelling and Grinding Equipment

- Sowing and Planting Equipment

- Pesticides Sprayers

- Tractor Mounted Sprayer

- Knapsack Sprayer

- Hand Tools and Machines

- Battery Operated Three Wheelers

- Army Equipment

- Army Uniform

- Army Body Armour

- Army Shoes

- Army Ballistic Helmets

- Army Tactical Bulletproof Vest

- Army Bulletproof Vest

- Anti Riot Armour

- Ballistic Overvest

- Bomb Blanket

- Bomb Detection Equipments

- Bomb Disposal Search Tools

- Army Caps and Hats

- Army Uniform Accessories

- Riot Drill Materials

- Army Tents

- Military Tents

- Solar System Products

- Ground and Underground Engineering Equipments

- Garage Workshop Equipments

- Garage Tyre Care Equipments

- Garage Lifting Equipments

- Garage Washing Dry and Clean Equipments

- Garage Crash Repair Equipments

- Garage Body Shop Equipments

- Garage General Service Equipments

- Garage Two Wheeler and Hydraulic Tools

- Garage Commercial Vehicle Equipments

- Garage Pollution Testing Equipments

- Garage Air Conditioning Equipments

- Garage Diagnostics Equipments

- Drilling and Bore Well Equipments

- 3D Printer Machine

- Agro Processing Equipments

- 3D Scanners Machine

- Water Irrigation Equipments

- Automobile Garage Tools and Equipment

- Diagnostics Car Scanners

- Wheel Aligner Machines

- Vehicle Diagnostic Scanner

- Vehicle Washing and Detailing Equipment

- Painting Equipment and Tools

- Vehicle Car Lifts and Hoists

- Vacuum Cleaners

- Nitrogen Generator and Air Inflators

- Wheel Balancing Machines

- Air Compressors

- Injector Cleaner and Testers

- Tyre Changer For HCVS

- Pollution Testing Machine

- Tyre Changers for Cars and LCVS

- Portable Car Jack

- Body Shop Equipment

- Dent Pulling System

- Hydraulic Jacks

- Tools Trolleys

- PUC Machines

- Vehicle AC Service Equipment

- Leak Locators

- Steam Generator Cleaner

- Vehicle Steam Cleaners

- Wheel Balancer for HCVS

- Truck scanner

- Smoke Meter

- Head Beam Aligners

- Portable Tilt Lift

- Shop Cranes

- Battery Testers and Analyzers

- Oil Bleeding Systems

- Auto Brake Riveting Machine

- Auto Wheel Repair

- Auto Post Lifter

- Auto Tyre Changer

- Auto Brake Drum and Disc Cutting Machine

- Auto Garage Tools

- Fire Detection System

- Fire Fighting Equipments

- Refrigeration and Cold Storage Equipments

- Cold Multideck Open chiller

- Cold Island Freezer

- Cold Meat Showcase

- Cold Room

- Cold Seafood Display Freezer

- Cold Upright Fridge and Upright Freezer

- Ice Maker

- Cold Cake Display Showcase

- Ice Cream Display Freezer

- Cold Fridge and Freezer Combine

- Cold Workbench Chiller

- Cold Kitchen Freezer

- Cold Wine Cooler

- Cold Mini Fridge

- Ice Cream Machine

- Wind Energy Equipment

- Computer, IT and ICT Equipment

- Cyber Security Equipments

- Traffic Safety Equipments

- Water Treatment Solutions

- Construction Machinery and Equipments

- Food Processing Equipment Line Machines Plants

- Aseptic Carton Filling Machine

- Filling and Packaging Machine

- Stainless Steel Tanks

- Preparation system

- Sterilization system

- CIP Cleaning System

- Carbonated Beverage Equipment

- Drinking Water Treatment Equipments

- Sanitary Pumps

- Installation Pipelines, Valves, Fittings

- Utilities Equipment

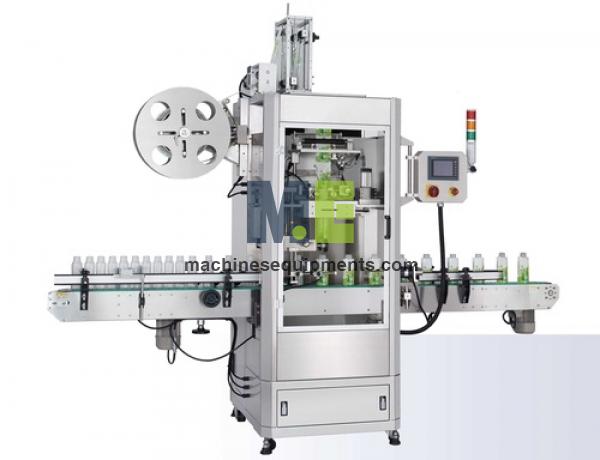

- Labeling and Packing Machines

- Strapping and Sealing Machine

- Bottle Filling and Batch Coding Machinery

- Fruit Processing Equipment

- Processing Plant

- Power Distribution Equipment

- Power Generation Equipment

- Power Transmission Equipment

- Food Processing Plants and Line

- Blogs